Les moules jouent un rôle-clé dans le processus de production. Ils assurent la qualité des articles produits et influent sur la conformité des produits finis (épaisseur, volume, défauts d’aspect, glaçures…). Il est alors indispensable d’avoir une gestion optimale des moules, autant à l’unité qu’à la série.

- Gestion homogène des moules

- Gestion des réparations

- Gestion des contrôles dimensionnels

- Suivi des échanges de moules inter-usines

- Connexion aux machines des contrôles dimensionnels automatiques

Pourquoi installer SILXMold

- Utilisation homogène de chacun des moules au sein d’une série pour plus de rentabilité

- Pleine traçabilité des moules pour des choix mesurés lors de l’achat de nouvelles pièces

- Productivité augmentée : plus aucune section arrêtée en raison d’un manque de moules ou d’un moule défectueux

- Communication plus fluide et forte réactivité au sein de l’usine

- Diminution du stock de moules

- Durée de vie plus longue des moules

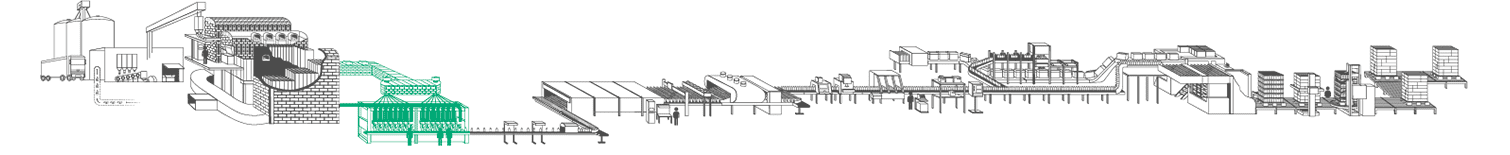

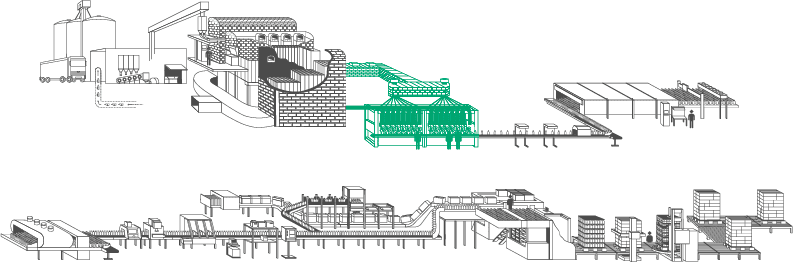

SILXMold dans l'usine

Fonctionnalités-clés

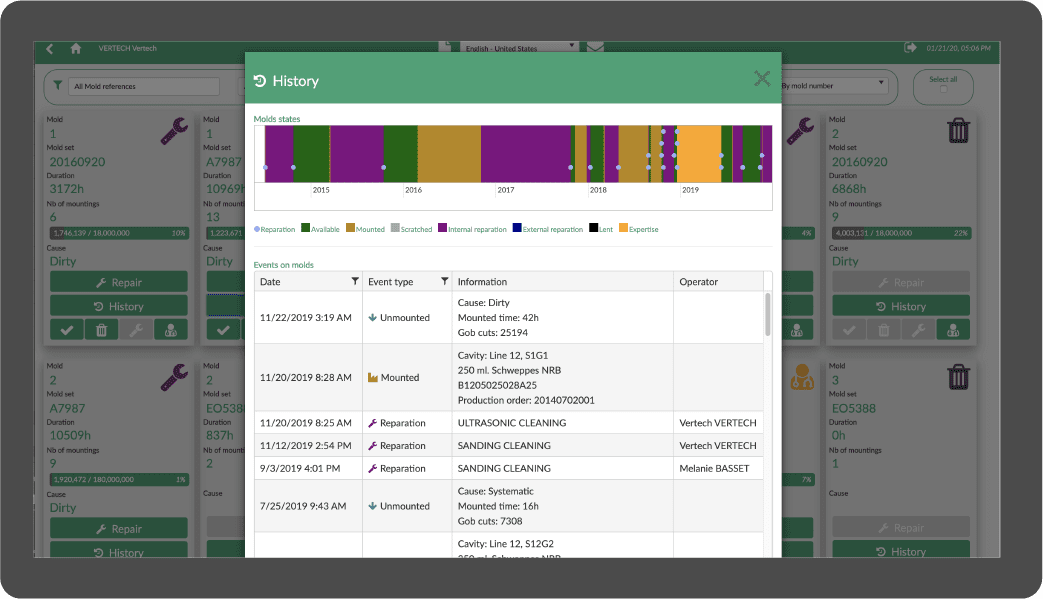

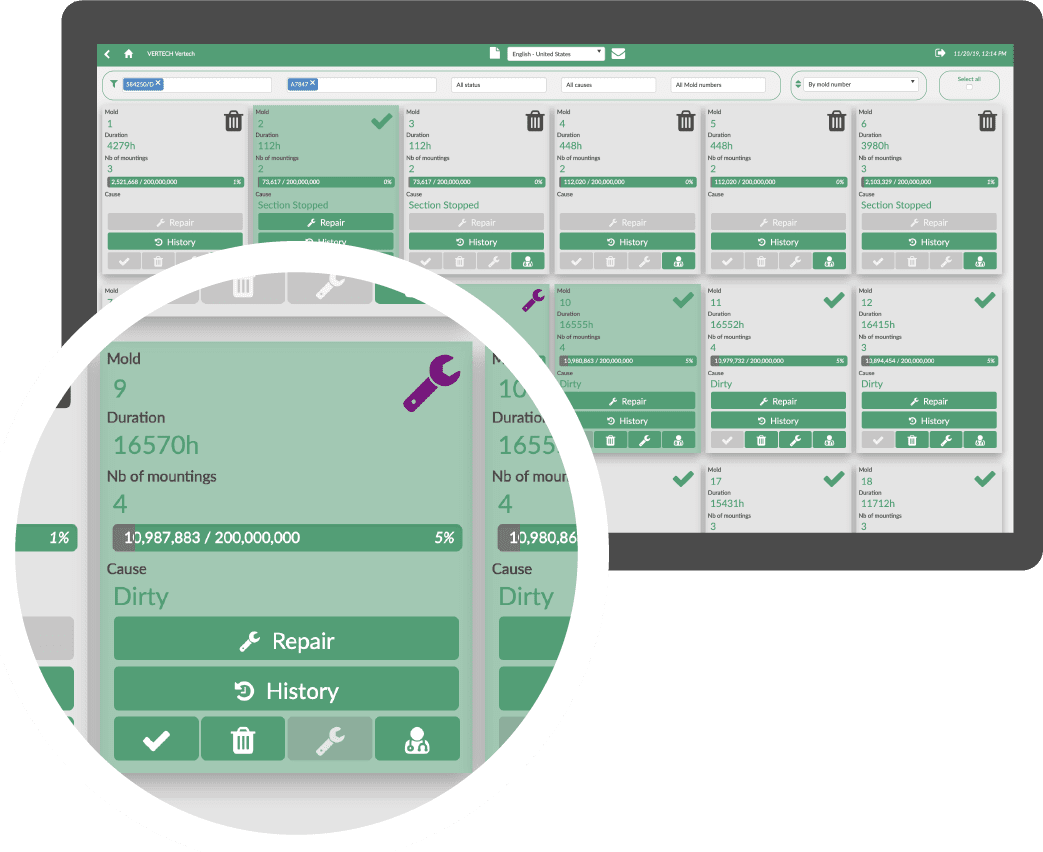

SILXMold contient un certain nombre d’informations sur chaque moule et indique leur statut en temps réel. Lorsqu’une réparation doit être réalisée sur un moule, l’opérateur consulte l’historique des réparations. Les contrôles dimensionnels sont également enregistrés, manuellement par l’opérateur ou automatiquement grâce à une connexion aux machines.

Cette pleine traçabilité rend les réparations plus rapides et efficaces, réduit fortement le risque de ne pas avoir de moules disponibles et donne tous les éléments nécessaires à des analyses sur la rentabilité des moules.