De nombreux paramètres peuvent avoir des répercussions sur la productivité d’un groupe verrier. C’est le contrôle, la supervision et le pilotage de l’ensemble de ces indicateurs qui garantissent la bonne santé d’une usine. Dans ce contexte, SILProd acquiert des données tout au long de la ligne de production et les affiche en temps réel.

- Acquisition de données

- Partage d’informations en temps réel

- Communication entre le BC et le BF

- Affichage des données en tableaux de bord

- Système de gestion de contenus (intranet)

- Digitalisation des procédures

- Enregistrement des contrôles

Pourquoi installer SILProd

- De nombreuses données affichées pour une hausse de la productivité

- Traçabilité pour des analyses et comparaisons détaillées

- Suivi des évènements pour une meilleure supervision de la production

- Communication et réactivité accrues au sein de l’usine

- Affichage des KPIs pour un suivi en temps réel de la performance d’une ou plusieurs usines

SILProd dans l'usine

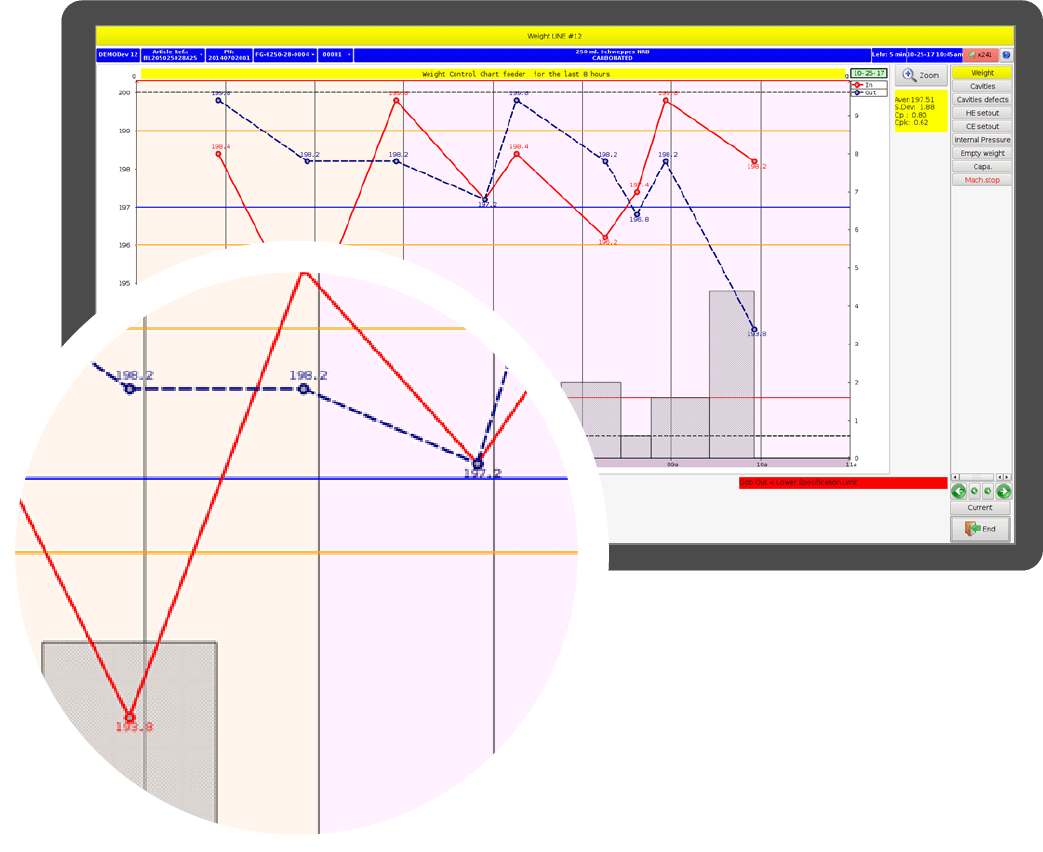

Fonctionnalités-clés

SILProd comporte de nombreuses fonctionnalités, comme le suivi du poids, les sondages ou les éjections systématiques, ayant pour objectif une supervision complète de la production. Les données sont acquises le long de la ligne et s’affichent en temps réel sur les postes SIL au bout chaud et au bout froid.

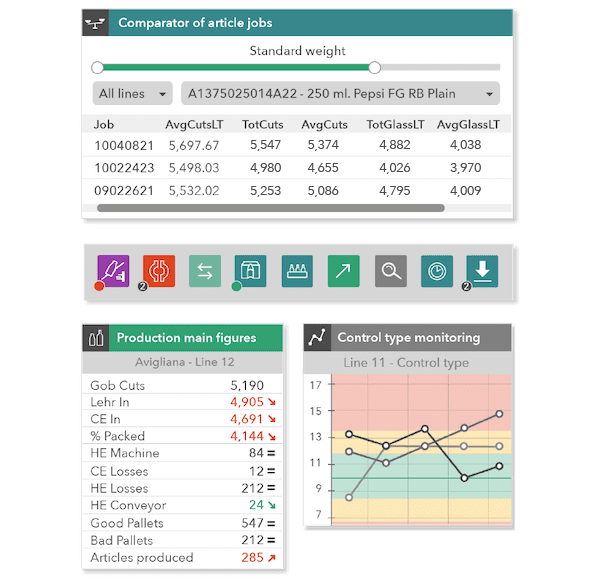

Au-delà de la ligne, ces données prennent la forme d’indicateurs-clés de suivi et de performance sur des tableaux de bord personnalisables. Rapidement, les responsables et directeurs peuvent donc par exemple connaître les pertes et rendements d’une ligne, d’une usine ou de plusieurs usines simultanément.