SIL4.0 accompagne les industriels en leur donnant toutes les clés pour répondre aux défis d’aujourd’hui et de demain. Les milliers de données acquises en temps réel partout dans l’usine sont indispensables pour piloter un groupe, analyser le passé et anticiper le futur.

- Acquisition de données partout dans l’usine

- Vos KPIs sur des tableaux de bord personnalisables

- Un projet individuel selon vos besoins

-

Corrélation

Pourquoi installer SIL4.0

- Anticipation des évènements de production

- Efficacité énergétique et productivité

- Contrôle total du processus de production

- Benchmark et amélioration continue

- Enregistrement des meilleures configurations

- Automatisation de tâches

- Digitalise la connaissance métier

- Réduit les erreurs humaines

- Abolit le papier, augmente la traçabilité

- Partage d’information

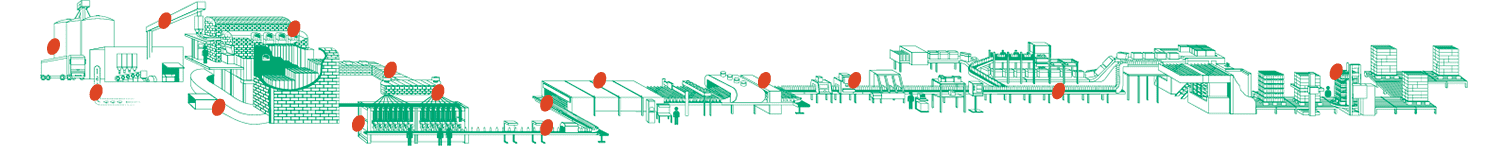

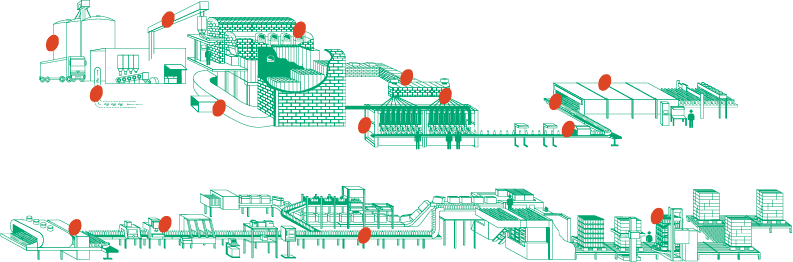

SIL4.0 dans l'usine

Composition

Bout chaud

Moulerie

Bout froid

Laboratoire

Management

Fonctionnalités-clés

Le principe de SIL4.0 c’est de digitaliser l’usine et les process de fabrication de la matière première jusqu’au produit fini.

Les KPIs ainsi récoltés sont essentiels pour superviser l’ensemble du processus de production et prendre des décisions rapides et justes. Un même tableau de bord peut d’ailleurs concerner plusieurs usines, ce qui facilite les comparaisons.