Le budget de maintenance est un poste de dépense important dans une verrerie. La gestion des pièces de machines SI est complexe et critique. L’optimisation des opérations de maintenance permet à la production d’atteindre sa pleine capacité.

SILXMaint transformera les données disponibles en informations utiles, qui mèneront à des décisions éclairées et à de meilleurs résultats commerciaux.

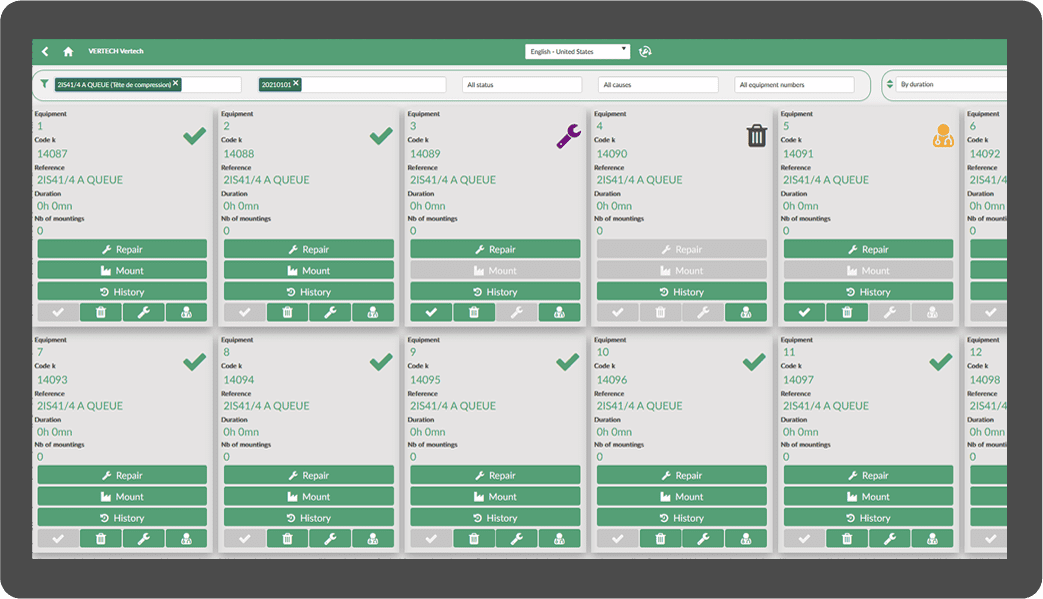

- Gestion des pièces telles que bras de transfert, pousseurs…

- Réparation et contrôle dimensionnel

- Traçabilité complète des pièces mécaniques

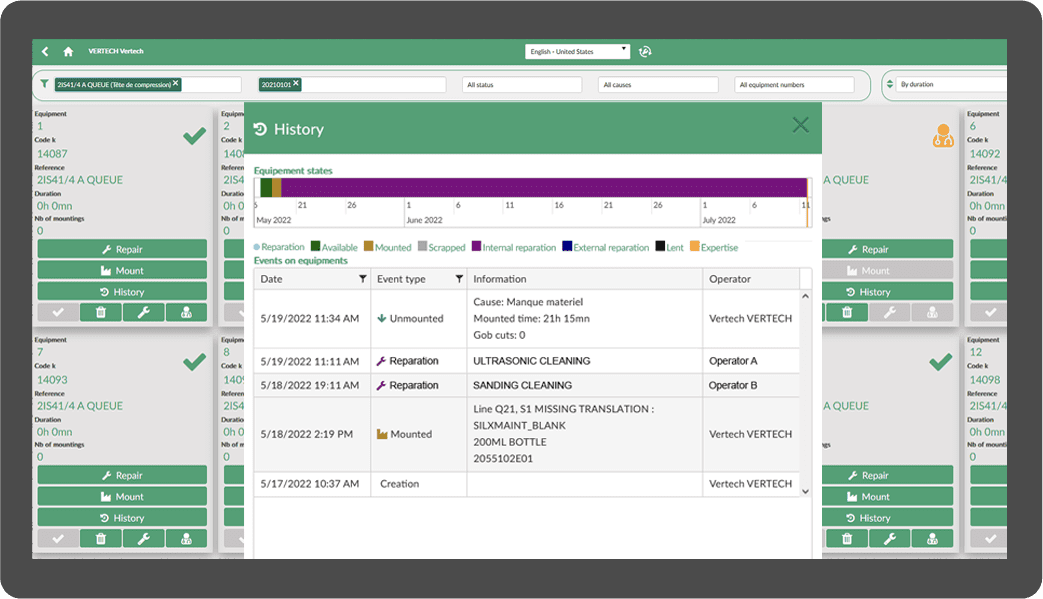

- Outils de reporting en temps réel et historique

- Suivi de la durée de vie des pièces mécaniques

- Déterminer les coûts d’entretien associés à

chaque production

Pourquoi installer SILXMaint

- Améliorer le rendement et réduire les coûts

- Gagnez du temps pour la préparation de nouveaux bons de travail

- Réduire les défauts répétitifs

- Sécuriser et optimiser le stock

- Analyser les réparations et les contrôles dimensionnels

- Assurer la maintenance prédictive

- Suivre la répartition des coûts d’entretien par tâche

- Faites le suivi de vos pièces

SILXMaint dans l'usine

Fonctionnalités-clés

SILXMaint fournira l’état en temps réel de chaque pièce mécanique, le module contiendra toutes les informations nécessaires relatives à l’utilisation de ces pièces. Il affiche toute la production en cours et à venir, de sorte que l’opérateur sera en mesure de les sécuriser, s’assurer qu’ils ont les pièces pour faire face à tout problème critique.

Basé sur les informations commerciales de réapprovisionnement des pièces peuvent être programmés facilement avec SILXMaint, vous sécuriserez la disponibilité des pièces nécessaires pour chaque production et de les attribuer correctement. L’exploitant organisera les réparations et les contrôles dimensionnels en fonction des prévisions de production et de la disponibilité des pièces. Vous aurez vos coûts d’entretien sous contrôle.